Desalination Pretreatment

Why a pre treatment before Desalination plant?

Reverse Osmosis Thin Film Composite membranes are subject to fouling by suspended materials that are present in seawater.

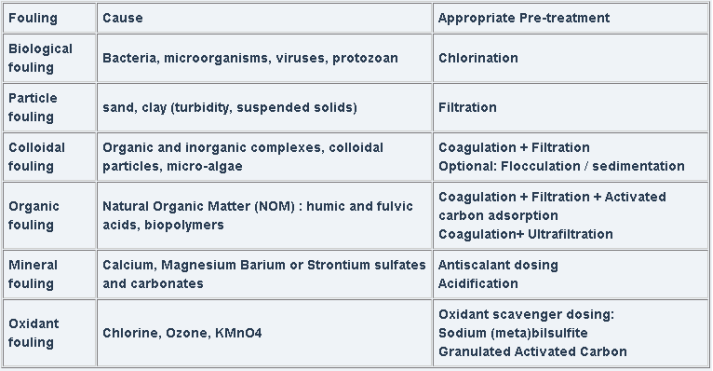

Typical seawater RO foulings are:

Seawater Desalination typical pretreatment processes:

A very cost-effective way to avoid biological fouling is seawater chlorination . Unfortunately, chlorine oxidizes the membrane material, therefore only 1000 ppmh can be tolerated.

A common dechlorination process is the injection of sodium bisulfite or metabisulfite, classified as a chlorine scavenger. Another solution is the use of a granulated activated carbon.

NOM, particles and colloids can be removed by so-called "conventional treatment" consisting of coagulation followed by deep media filtration for low turbidity water . Additional steps such as flocculation and sedimentation are added in case of very turbid shallow seawater.

The non-conventional pretreatment for NOM , particles and colloids is ultrafiltration.

An antiscalant solution should be dosed before the reverse osmosis membranes to disperse calcium carbonate and sulfates precipitates in order to avoid scaling.

Fine filtration (5-micron) is required as a last step before the RO membranes to prevent any debris, sand particles or piping material to damage the membranes.