The application field of composite tubular membrane

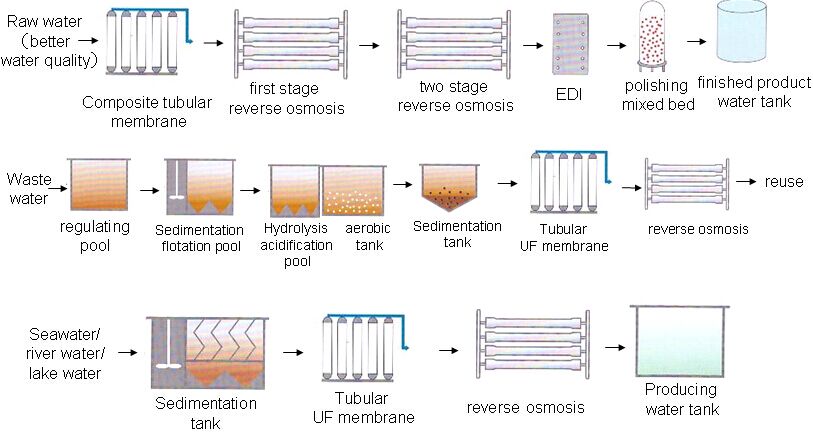

(1) Gray water reuse

Function and efficacy of composite tubular membrane:

Reducing the water turbidity and suspended solids content, reducing COD, BOD, chroma and oil content, in order to achieve the discharge standard;

Deep processing wastewater by membrane method, in order to achieve the requirements of water reused for production and cyclic utilization;

Recycling the useful material in waste water to used in the production.

Applications segmentation:

Deal with municipal sewage, cutting wastewater, electrophoretic wastewater, painting wastewater, oilfield reinjection water (including oil wastewater), textile wastewater, paper wastewater, leather wastewater, heavy metal wastewater, emulsion wastewater, printing and dyeing wastewater, laundry wastewater, domestic sewage, electroplating wastewater, electronic circuit board wastewater, coal mine wastewater, steel wastewater, power plant wastewater, petrochemical wastewater, and other various industrial sewage and wastewater.

(2) drinking water

Function and effect of composite tubular membrane

Function: degerming, turbidity removal, impurity removal, water purification

Effect:

1. Remove muddy sand, iron rust, etc suspended solids;

2. intercept e. coli, giardia, various bacteria and virus;

3. Remove various microorganism;

4. Remove humic acid, humic, etc Macromolecular organic matter.

Applications segmentation

Municipal drinking water(tap water), mineral water(spring water, mineral water ), purified water(purified water,pure water)dual water supply(direct drinking water)

Household water purification(water purifier), Rural water supply(rural town treat surface water ,well water for drinking)

(3) Industrial pure water

Function and effect of composite tubular membrane

•Degerming, microorganism removal, colloid removal, Impurities and particles removal;

•Reduce water turbidity, SDI,COD,BOD;

•As the pretreatment of RO, supply good quality feed water, protect RO membrane;

•Ultrafiltration is used at the after end of finished product water to remove particle and prevent secondary pollution;

•Remove Macromolecular organic matter.

Applications segmentation

•Treatment of process-water, production process water:

•drinking water, medical water, water used for food, beverage, wine

•Pure water for various industrial production, ultrapure water

•RO pretreatment or after treatment, Ion Exchange or EDI pretreatment or after treatment.

(4) Special separation

Function and effect of composite tubular membrane

•Extract the material needed

•Recycle the substance needed

•Keep the flavour of effective components, remove the components which produce turbidity, affect flavour and guarantee period

•Concentrate the concentration or content ratio or substance needed.

Applications segmentation

•Clarification and concentration of gelatin;Vinegar clarification; electrophoretic paint recycling; percolating water reuse;

•Purification and of dairy product; purification, concentration and impurity removal of Chinese drugs pharmaceutics;

•Purification and concentration of juice, clarification and turbidity removal of White wine, rice wine, red wine, grape wine;

•Fiber processing solvent recycling; recycle wool fat from fine wool wastewater.

•Purification, concentration and separation of various biological products

•Filtration and clarification of various oil